Sri Lanka›s automobile assembly is experiencing significant growth and development with the involvement of world-renowned brands including Hyundai, Proton, BAIC, DFSK, Wuling, Mahindra, TATA, Bajaj, TVS, JMC and Lanka Ashok Leyland emphasizing the favourable environment for investment.

The approval to assemble a wide range of vehicles including SUVs, Cars, Two-Wheelers, Double-cabs, Trucks and Buses has paved the way for a diversified automobile assembly industry in the country catering to various consumer needs. Nwow electric bikes, KD Rize, Dyno and Senaro are also involved in the local assembly of motorcycles.

Over four assemblers including JAC and FOTON will be starting assembly in Sri Lanka and by the end of the year over 30 assemblers will be in operation in the local automobile assembly industry.

These world-renowned assemblers must provide a domestic value addition of more than twenty percent by using locally manufactured automobile components. Many of the local component manufacturers have gone through an extensive product development and product approval process to maintain the global original equipment (OE) standards maintained by the international brands.

With an increase in both component manufacturing and assembly, the industry is poised for a period of further expansion.

Following the Standard Operating Procedure (SOP) launched in 2021, there are over fifteen automobile and motorcycle assembly plants currently operating in Sri Lanka. Four more assembly plants are due to begin operations within the next three months and another eleven have been registered by the Ministry of Industries. A Special Cabinet appointed Committee oversees the SOP and its governance.

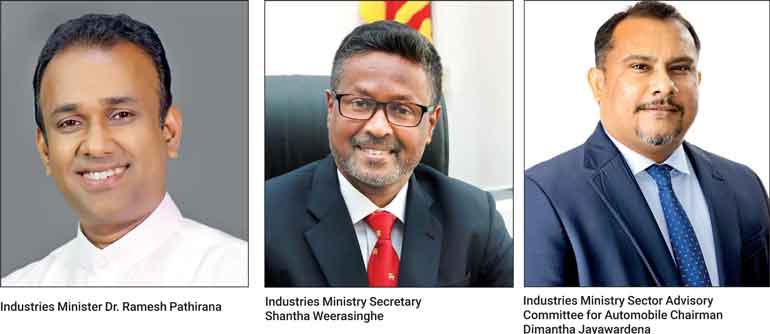

Industries Ministry Sector Advisory Committee for Automobile Chairman Dimantha Jayawardena said: “Sri Lankan automotive component manufacturers went through one of the toughest business cycles from 2020. The Sri Lanka Government is promoting automobile component manufacturing as a thrust sector for growth and has a plan to grow exports from $ 200 million to $ 1 billion.

The temporary suspension on motor vehicle imports has increased the market for locally assembled vehicles. The planned establishment of an R&D and testing facility by the Industrial Development Board (IDB) indicates a commitment to innovation and quality assurance within the industry, to further enhance Sri Lanka’s competitiveness in the global automotive market. The Automobile Industry Council (AIC) initiated by the Government is also laying out the curriculum for the required technical and vocational education for automobile assembly.”

The Industries Ministry is sponsoring 50% of the cost of the International Automotive Task Force (IATF) certification for local automotive component manufacturers which is a mandatory requirement when manufacturing components for international brands. Sri Lankan companies with the IATF certification will have greater acceptance and trust from global brands for automobile assembly. “The consistent and collaborative policy of the Government is greatly appreciated by the automotive assembly industry. Global brands are also keen to invest in Sri Lanka because the country lies astride major supply chains linking trade between the east and west. More and more Sri Lankan consumers are also showing a preference for locally assembled vehicles. This is a great boost to the industry as it further creates engineering and technical-related jobs,” Jayawardena said.

“The Industries Ministry Sector Advisory Committee is looking into supporting all the prospective assemblers and component manufacturers to increase jobs up to 45,000 in the sector and to make Sri Lanka a global automobile manufacturing hub by 2037, in keeping with the 20-year master plan for the automobile assembly industry,” he added.